Your shopping cart is empty.

Paper vs Control: How are you measuring tools?

By JBM Applications Engineer, Drew Guldalian

In many parts of the manufacturing world, there is always more than one way to do something. However, the end goal is the same: get the best product possible without taking a loss on the method used.

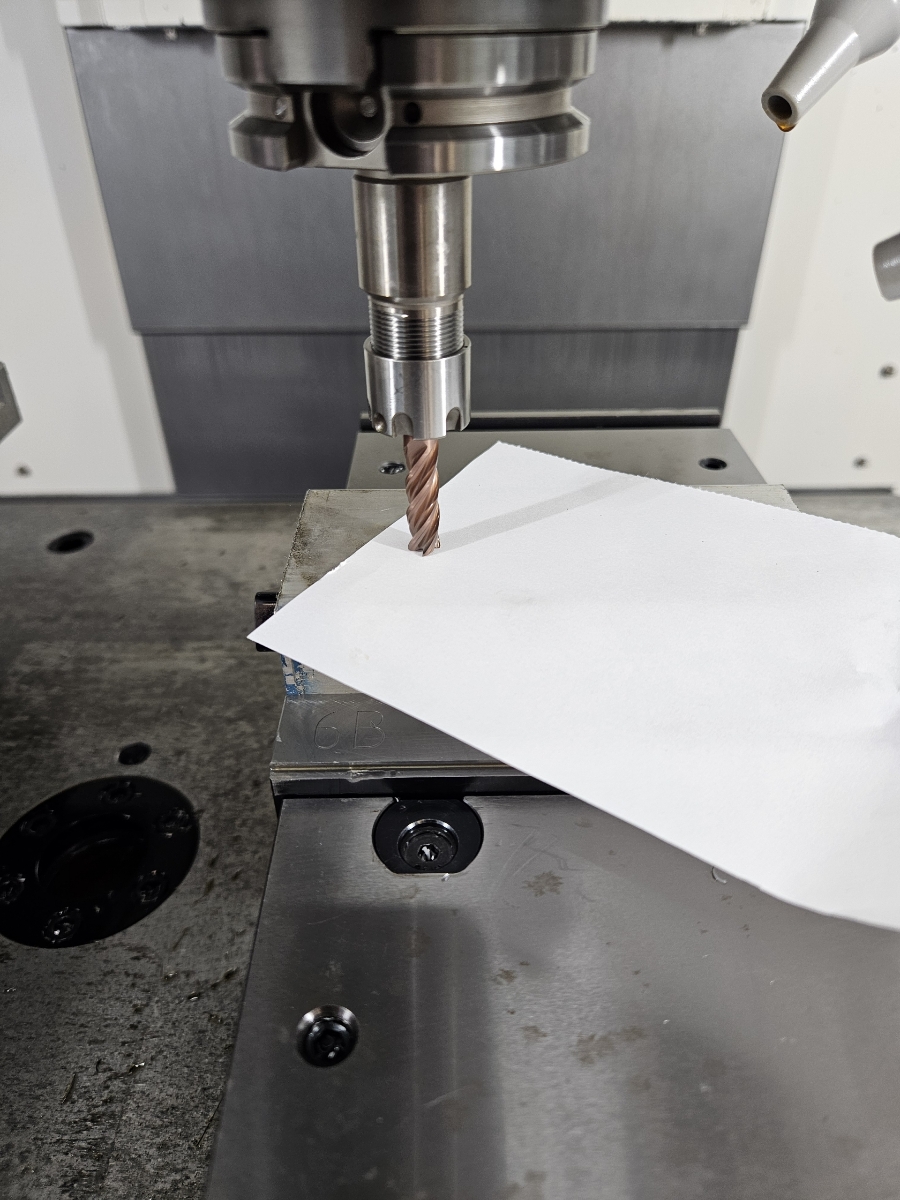

Measuring tools is a critical step in using a machine tool. You can have some very old equipment with accurate tool measurements making great parts, and you can have a new machine with inaccurate measurements making subpar parts. It is near impossible to make a good part when starting with tools that are not correctly measured. Here is where many people can have a different approach: you can measure tools with as little as a piece of paper, or as much as an offline station that measures them, then inputs the information into the machine.

The myth is that using anything other than a piece of paper costs too much, but time is money and constantly measuring tools takes time. Adding a tool setter to a used machine is just as important as getting it when purchasing a new machine. They are incredibly repeatable and that is the key- repeatability gets you consistent parts. The trick to using a tool setter efficiently is to identify key points in your manufacturing process to use it, such as:

- in a blending feature

- after a roughing endmill, before a finishing endmill

- checking for a broken drill before a tap

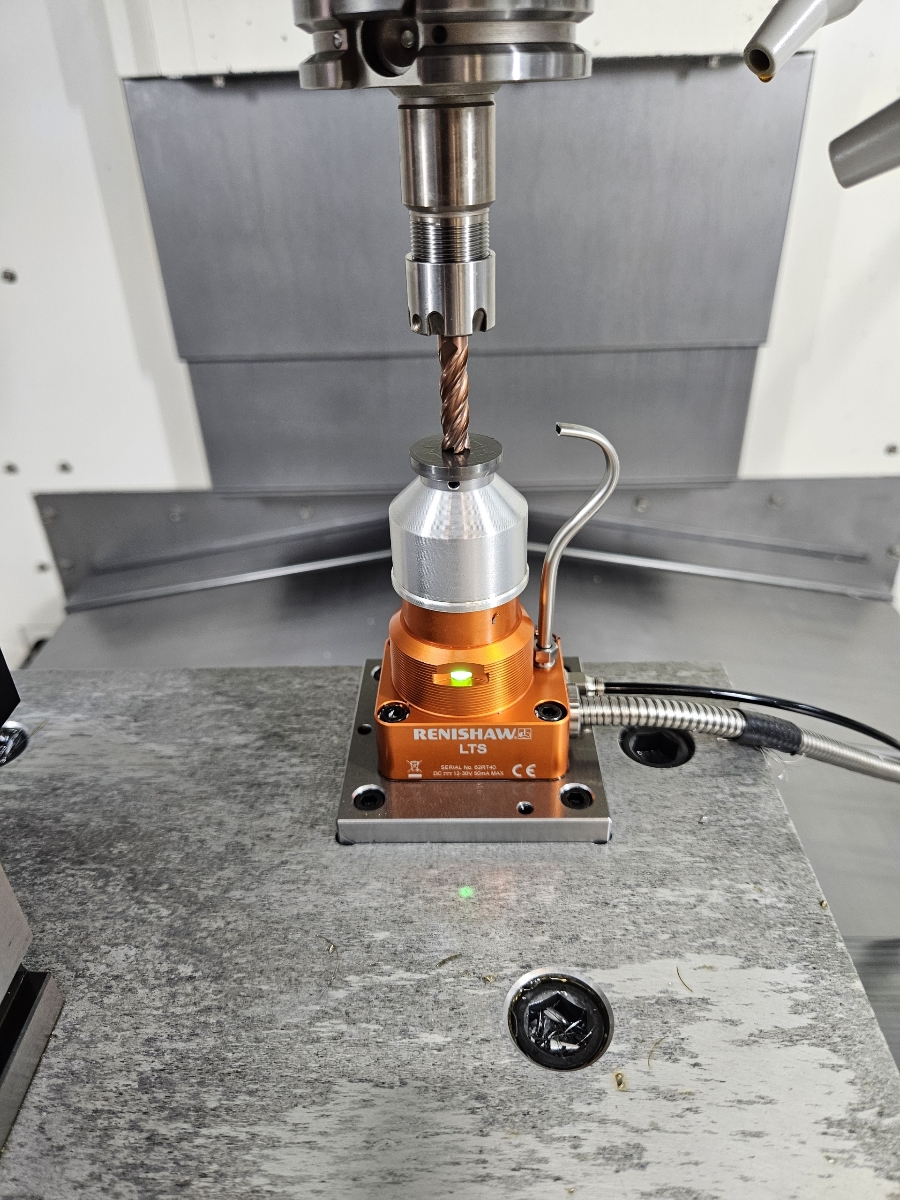

Renishaw has spent a lifetime perfecting their products, and it shows. They offer excellent customer support and a full line of products at various price points. If all you want to do is measure the length and check for broken tools, the LTS is for you. If you want to measure diameter as well as length, then JBM’s tool setter of choice is the OTS. For micro tools or higher tolerances, the NC4 laser will be for you. JBM installs and trains on these varieties on used and new machines alike.

Renishaw has spent a lifetime perfecting their products, and it shows. They offer excellent customer support and a full line of products at various price points. If all you want to do is measure the length and check for broken tools, the LTS is for you. If you want to measure diameter as well as length, then JBM’s tool setter of choice is the OTS. For micro tools or higher tolerances, the NC4 laser will be for you. JBM installs and trains on these varieties on used and new machines alike.

The one I want to focus on is the LTS for a vertical or horizontal machining center. The LTS is an affordable option to add to an existing machine and will yield better parts instantly. You will have good blending, consistency in heights, and no more broken tools from missing a drill that mysteriously turned into a broken tap. LTS tool setters are typically a one day install and easy training. I highly recommend adding them and proving that the cost of probes is not out of reach.